従来加工案

❌ お客様はこのような微細超深穴の成熟な加工案を持っていない

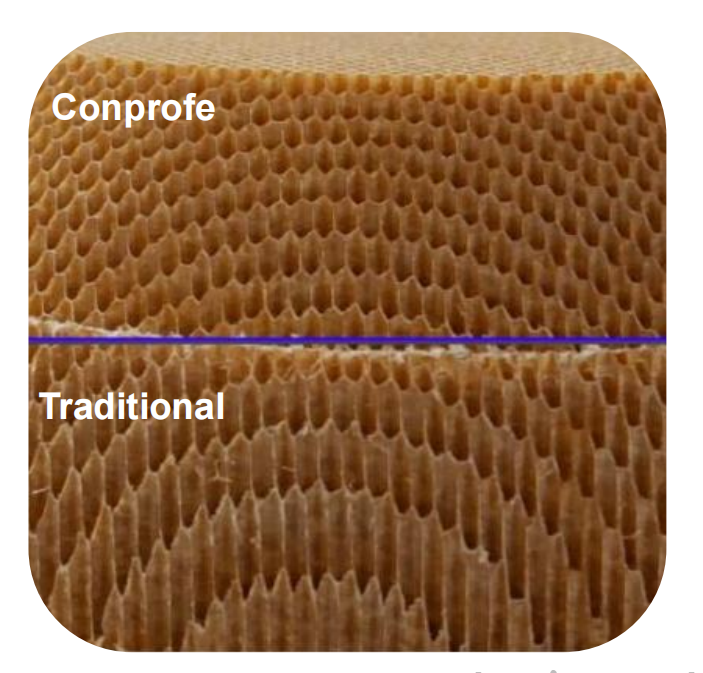

❌ 穴壁の粗さSa ≥6.54μm

❌ 穴の真円度 ≥0.025mm

❌ 穴の垂直度は保証できない

CONPROFE加工案

🔔 超音波精密彫刻フライスマシニングセンタULM-600

🔔 超音波加工技術

🔔 一体式PCDマイクロドリル

加工の優位性

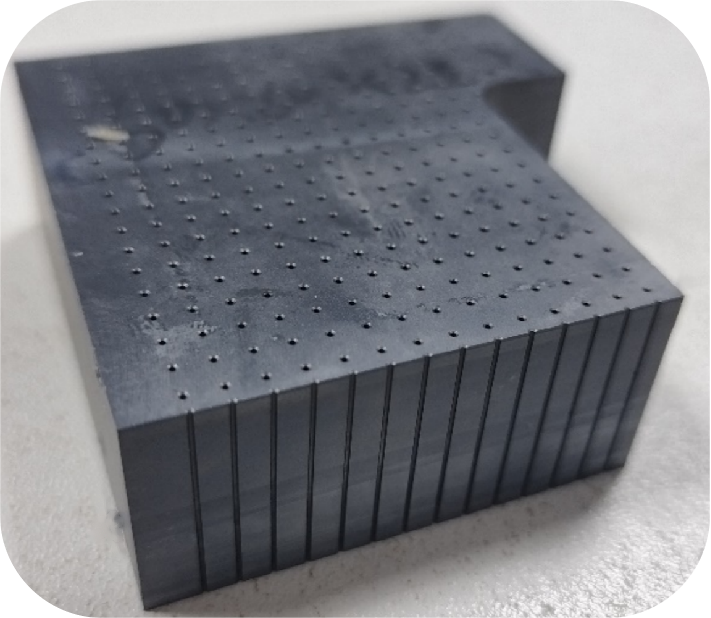

✅ PCDドリルはD0.45*24.75mmの微細超深穴を連続で2000個加工できる(アスペクト比55:1)

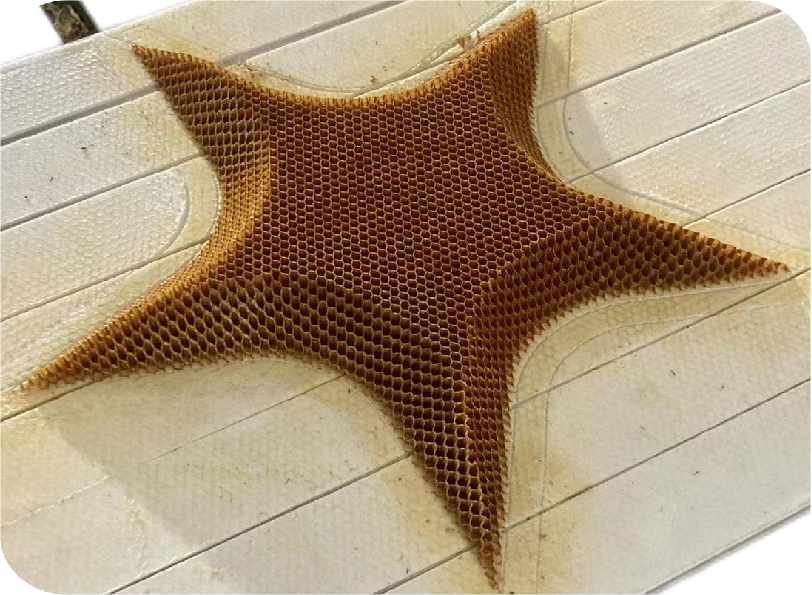

✅ ブラインド穴加工、穴の入口部はチッピングがないと目視で確認できる

✅ 穴の真円度が0.003㎜

✅ 穴壁の粗さは6.540μmから0.013μmへと99.8%低減