Conprofe Benefits

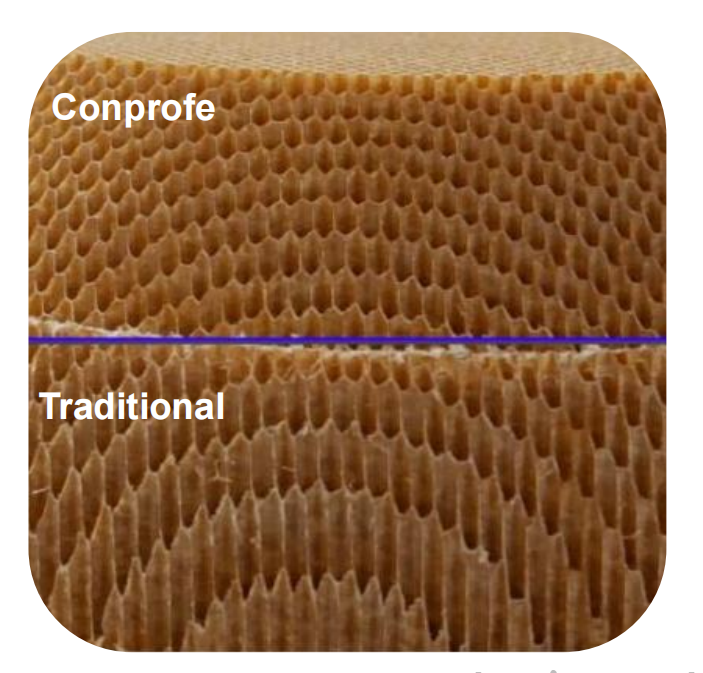

✅ Lower surface roughness

✅ Profile tolerance consistently within 0.01mm

✅ 14 times tool life increase, from 100 to 1500 pieces

Conprofe Benefits

✅ Lower surface roughness

✅ Profile tolerance consistently within 0.01mm

✅ 14 times tool life increase, from 100 to 1500 pieces

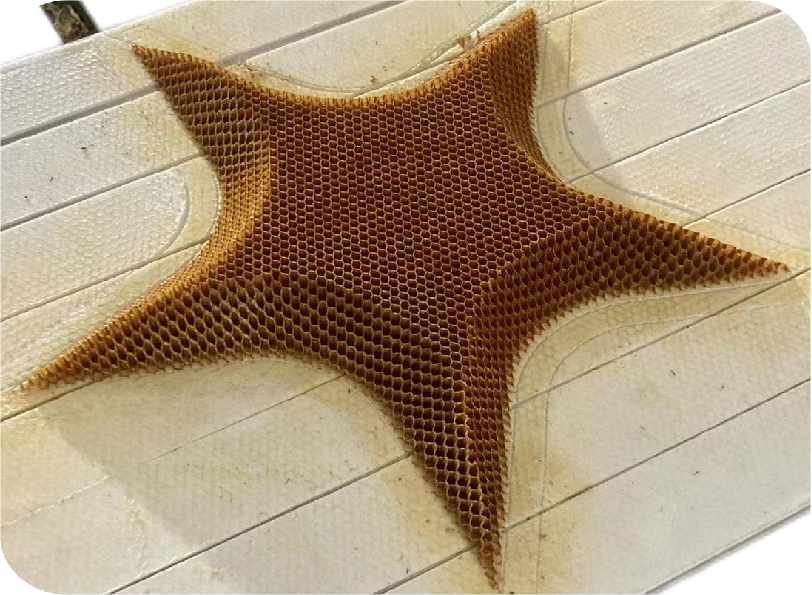

Workpiece

🔔 Aluminosilicate Glass

🔔 120 x 60 x 2.2mm

🔔 Required Roughness Sa < 600nm

Challenges

❌ Failure to meet roughness: Sa 800-1000nm

❌ Unrealizable to mass production due to short tool life

❌ Profile tolerance > 0.05mm

Conprofe Benefits

✅ Lower surface roughness

✅ Profile tolerance consistently within 0.01mm

✅ 14 times tool life increase, from 100 to 1500 pieces