Challenges

❌ Low machining efficiency

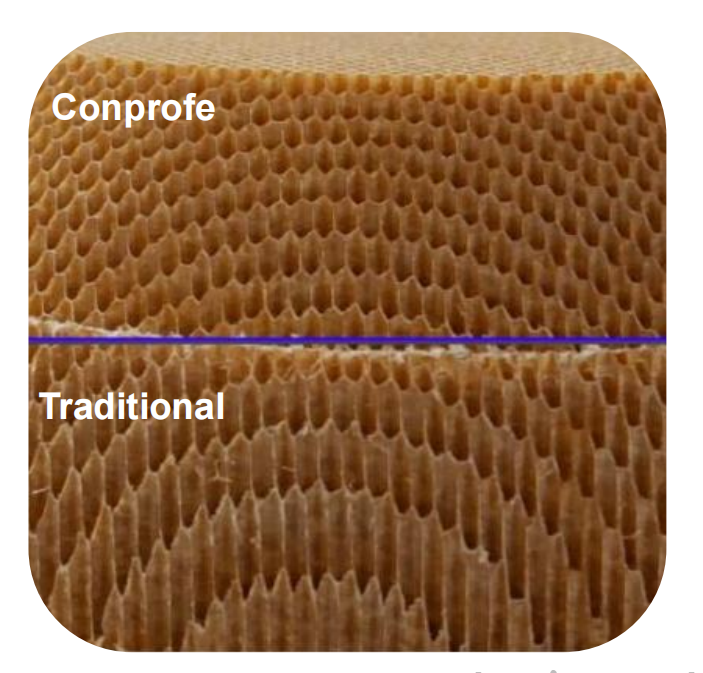

❌ Vulnerable to hole edge chipping

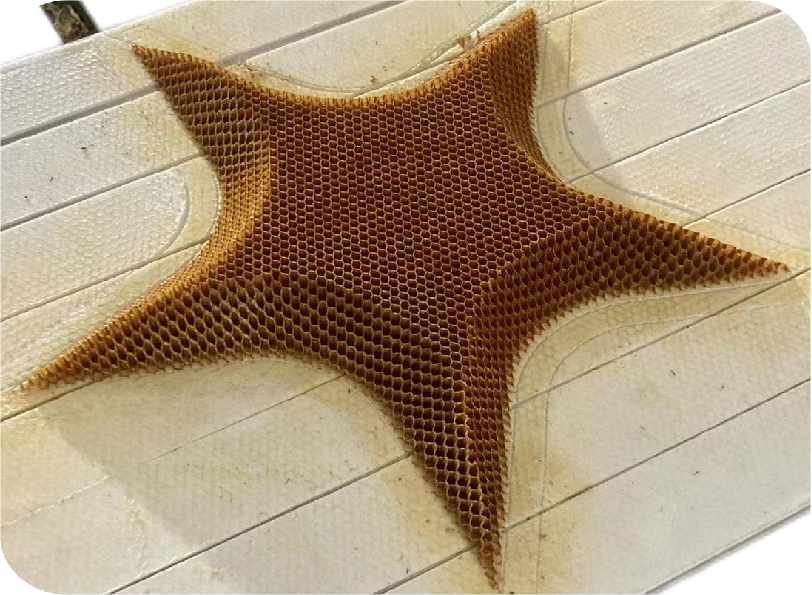

Conprofe Solution

🔔 Ultrasonic Precision Engraving and Milling Center ULM-600

🔔 Ultrasonic Machining System

🔔 Solld PCD Drill

Conprofe Benefits

✅ Continuous drilling of 1,200 D0.5x5mm holes

✅ Cycle time reduced by 72%, from 270s to 75s per hole

✅ Hole edge chipping decreased by 68%, from 0.4mm to 0.13mm