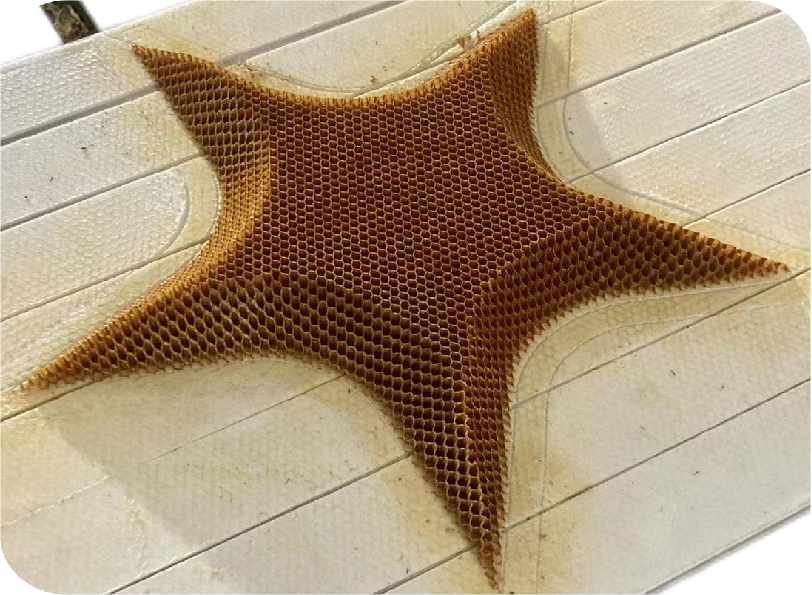

Workpiece

🔔 Superalloy

🔔 Hole: φ0.5/0.6/0.7mm

Challenges (Laser+EDM)

❌ Long cycle time with EDM: 150s

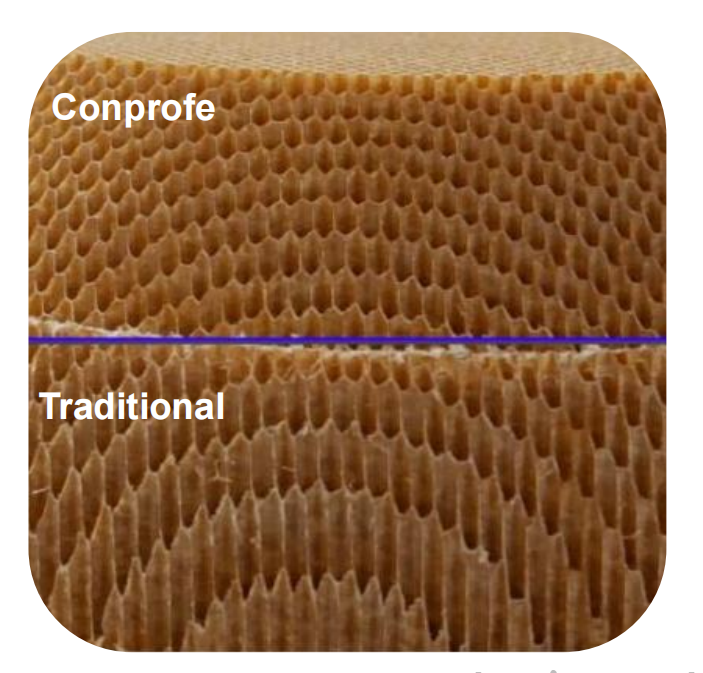

❌ Engine blade service life shortened by EDM recast layer

Conprofe Benefits

✅ Lower cutting force and significant burr reduction

✅ Qualified hole dimensional accuracy

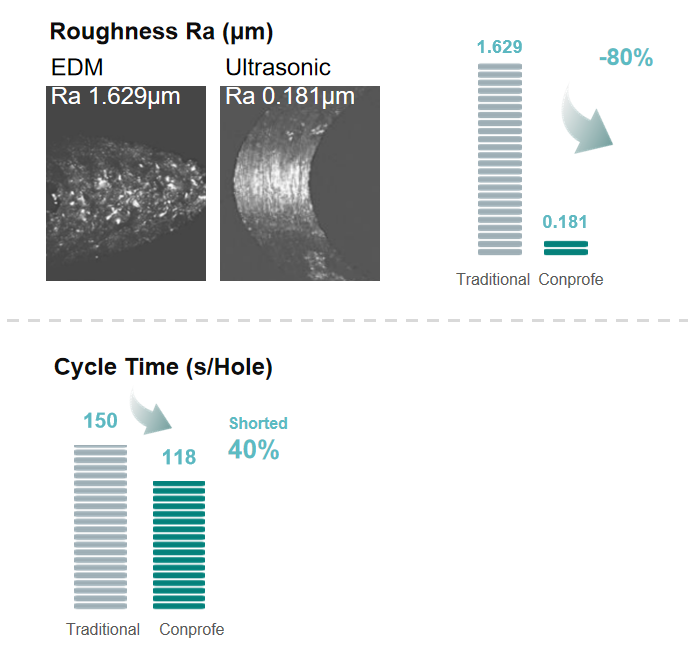

✅ Hole wall roughness decreased by 88%, from 1.629μm to Ra 0.181μm

✅ Cycle time shortened by 40%