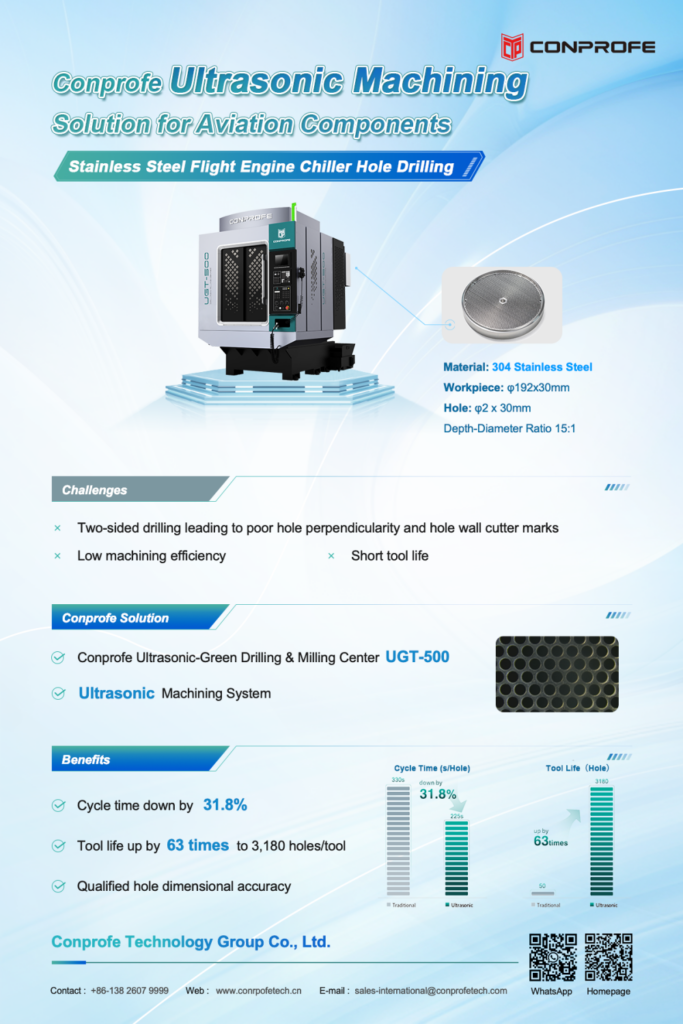

With traditional machining solution, one of our customers in aviation industry has faced some challenges when they wanted to drill holes in flight’s engine chiller made of 304 stainless steel, such as in low efficiency, short tool life and also severe cutter marks on hole wall.

Therefore, in order to tackle their worries, we provided Conprofe solution – Drilling and Milling Centers with Ultrasonic Machining System. The cycle time was reduced by 31.8%, tool life was improved by 63%, and hole quality & accuracy were also improved. With our Ultrasonic Machine Tools, we managed to maximize the machining performance and eventually resolved the problems for our customer.

For more application examples or test-drilling of aviation part, please feel free to contact Esther Hu, Senior Director of Overseas Sales and Marketing.